Extension for craft beer

The buildings of traditional breweries are still common today and have shaped the appearance of many a town over many eras. Therefore, they can be well implemented as a theme on dioramas. The Faller kits of the “Peschl Brewery” and the “Industrial Hall under Construction” inspired Heinz Hofmann to combine both on a single diorama.

After some young brewmasters had acquired the mothballed brewery, they renovated it in order to subsequently brew craft beers. Since these beers are selling like hot cakes, the storage capacity for raw materials and finished products in particular is due for expansion by adding a modern warehouse made of precast concrete elements.

Construction of the brewery

Construction begins with the bonding of the brewing kettles, which are already sprayed copper-colored at the factory. The boilers are then glued to the brewhouse floor plate and fitted with numerous finishing parts and piping. During this construction phase, the railings around the brew kettles are also attached. Then, the two side walls and the rear wall are glued to the base plate. It should be noted that the decorative arch for the wall facing can then be easily inserted between the railing and the wall. Lighting for the brewing room is recommended, as otherwise nothing would be visible of the well-made interior design due to the darkness. The rest of the construction is done according to plan. Once all three parts of the building have been assembled, they are joined and glued together. Before gluing, the cables for the lighting must be laid from the central part of the building into the outer buildings and down to the base plate. Openings for this are provided, but must be opened. Next, the installation of the roofs, the small turrets, and the all-around tile roofing and crenellation covers will continue before construction of the chimney can be started. Like the roof surfaces, this will be subjected to a slight aging process.

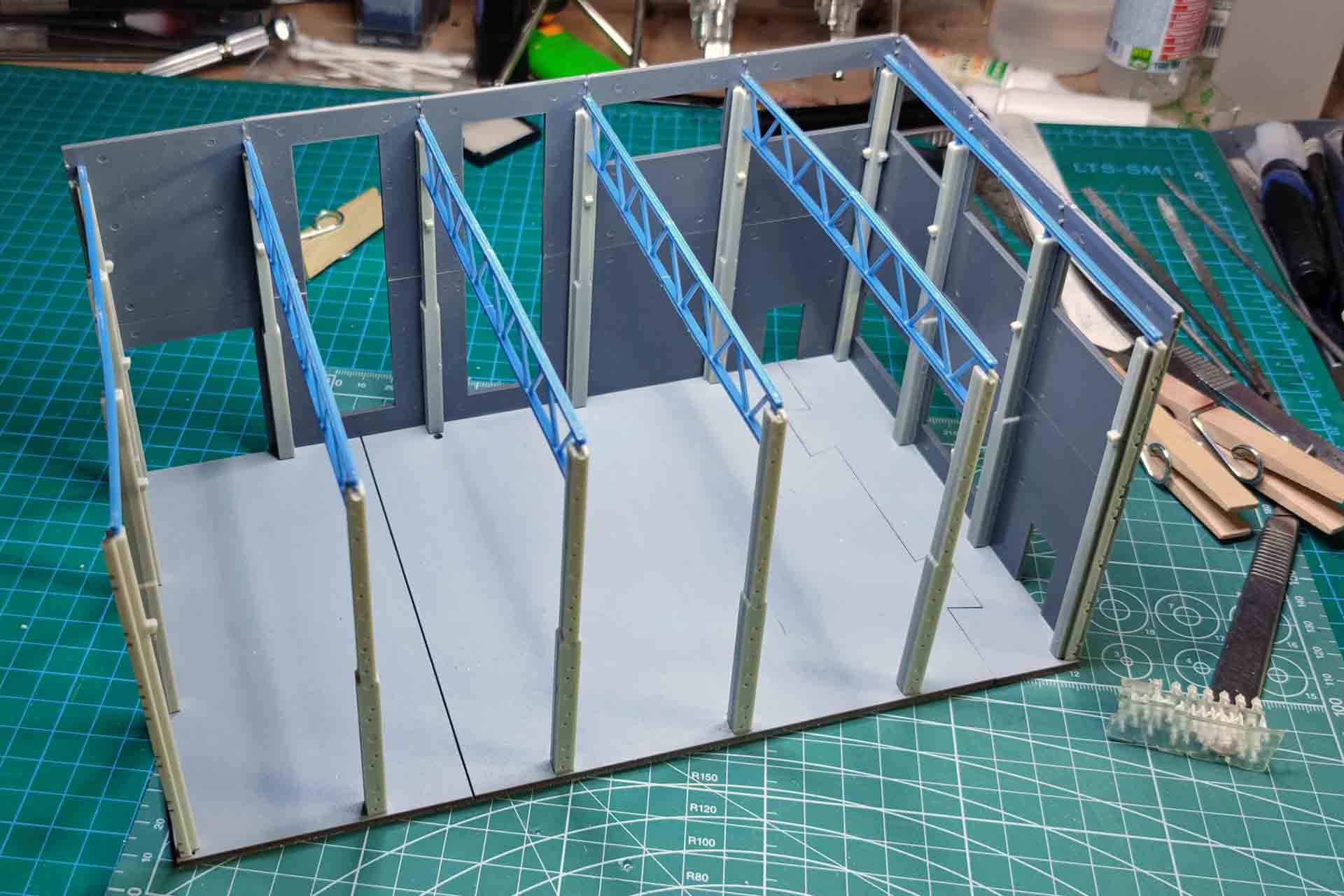

On the construction site

The new warehouse is built from components of the Faller modular system and is thus easy to assemble. A small temporary office provides space for the construction management and the staff’s social rooms. During the renovation, the new brewery owners make sure that many insect-friendly plants find their home around the building. They have conquered the site during the long shutdown and are to remain as far as possible. In addition to a varied flora, some four-legged furry friends have also settled on the company premises. In addition, the chimney has been given a stork’s nest, inhabited this year by friend Adebar, as storks are sometimes called in Germany. This one comes from Faller, as do the two other animal inhabitants on the showpiece.

Everything that goes with it

Once the buildings are finished, they are placed on the base plate. The old part of the plant is placed on the left, the new hall and the construction containers on the right. Solvent-free all-purpose adhesive is used to glue the buildings to the base plate. The road, the inner courtyard, and the ground surfaces in the construction site, as well as the meadow area, are designed with texture paste from Joker Rügen. In order to achieve an even truer-to-the-original appearance, real fine earth is sprinkled into the still moist texture paste in some areas. Likewise, before the paste dries, you could add some grass fibers to it with a flocking device, without having to apply glue again separately. For designing the meadow areas, various seeding tufts, edging strips, and prairie grasses in various colors are used in addition to hedge roses and some buckthorn bushes from Lars op ‘t Hof. Individual pieces of Noch groundcover foliage are also “planted” in some places. The tall birch behind the brewery building is from Woodland’s Classic series. Now, the iron fence is also set, which stretches around the old operating area. It is glued to the base plate with super glue.

Finish

Now, it’s time for the finishing. First, the compressor from Faller’s construction site equipment set finds its place inside the half-finished hall. Also from this set are vibrators and rammers, which are used to compact the soil and the applied ballast. Next to the six-axle mobile crane from Baumann, a semitrailer truck is parked on the road. the road. This one has delivered the last steel girder, which will be placed on the concrete supports by the crane. In the construction site area, there are still two construction site vehicles from Herpa, the Strabag transporter comes from Busch. The construction site fences that can be seen are from the Faller program.

Everyday scenes of a brewery

On the brewery’s loading ramp, numerous aluminum bottle crates and beer kegs are stacked, waiting to be picked up, or which were delivered empty. Two delivery trucks are parked in the ramp area, one from Herpa and one from Busch. The drivers are currently loading them by hand with beverage crates. With the completion of the new hall, the loading of the customers’ vehicles will certainly become a lot easier ... To the left in front of the ramp, employees of the brewery have parked their private cars. In front of the iron fence, Harald, the fast-paced reporter of the local newspaper, is taking some snapshots of the construction work. Perhaps, however, he is photographically targeting the two yard workers, who are adopting a very relaxed working posture at this moment. In any case, he’s in a hurry once again, because he hasn’t exactly parked his Ford Kuga perfectly ...