Herpa’s second beginning

Strictly speaking, the Herpa company has two beginnings. Firstly, on 9 March 1949, the "Wilhelm Hergenröther - Fabrikation Nürnberger Qualitätsspielwaren" company was officially registered as a manufacturer of toys and household objects. It began production in barracks in the destroyed city of Nuremberg, expanding to Beilngries facilities in the 1950s. A little later, Fritz Wagener founded a plastics company in Nuremberg in 1961, eventually taking over Herpa and developing it into the company it is today.

After the end of the war, Fritz Wagener set up a small engineering office to work with contacts in the photographic industry in Nuremberg. He soon became a permanent employee at Bolta-Werke, first as a design manager and later as plant manager. This job took him to America, which was much more advanced in injection moulding technology than Germany. This allowed him to develop his expertise. Urged to do so by friends, he set up a new business, with his first orders coming from Camerawerk Braun.

It begins for the photography industry

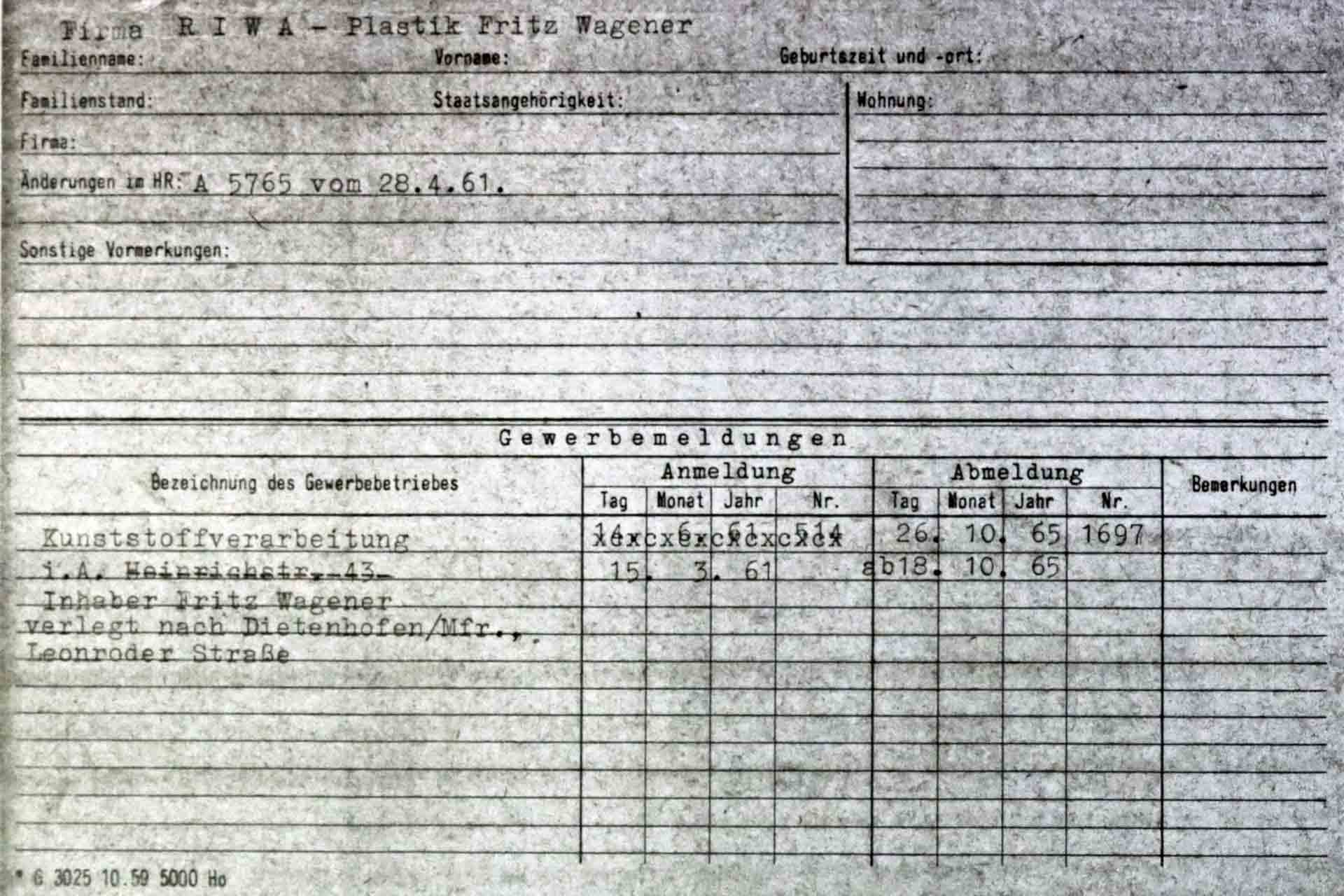

On 15 March 1961, engineer Fritz Wagener registered his company RIWA in Nuremberg. The company was actually to be called FRIWA, an acronym made up of the first letters of Wagener's first name and surname, but there was already a hairdressing company of the same name. Wagener pragmatically deleted the first letter and RIWA was founded.

The trade register of the city of Nuremberg listing RIWA-Plastik – Fritz Wagener.

The company began with the production of plastic parts for the photographic industry, such as slide frames, gear wheels, and blades for fans. The first production site was in a former car repair shop in Nuremberg-Schweinau.

The first machine is delivered.

Nothing was available, everything had to be purchased, from tools to machines, to office equipment, packaging materials, and raw materials - with only 40,000 marks in start-up capital. Even the water mains had to be replaced to cool the machines. To do so, the road was dug up without further ado.

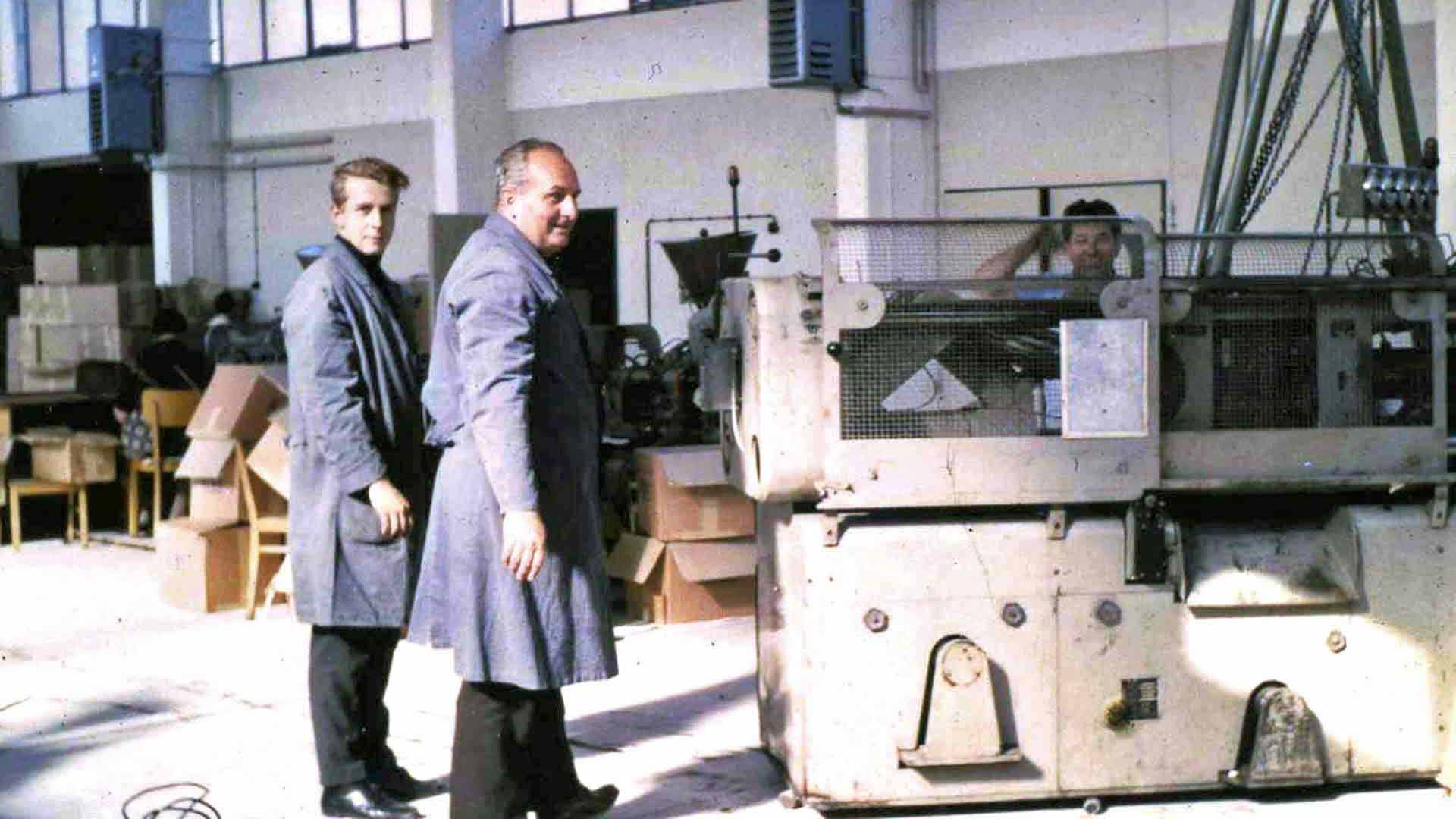

Production started on 29 March with the first employee, 15-year-old son Claus, who became the first and only sprayer. A sign on the company building advertised the need for more employees for production, payroll accounting, invoicing, packing, and as labourers. Meanwhile, the boss was primarily responsible for new orders.

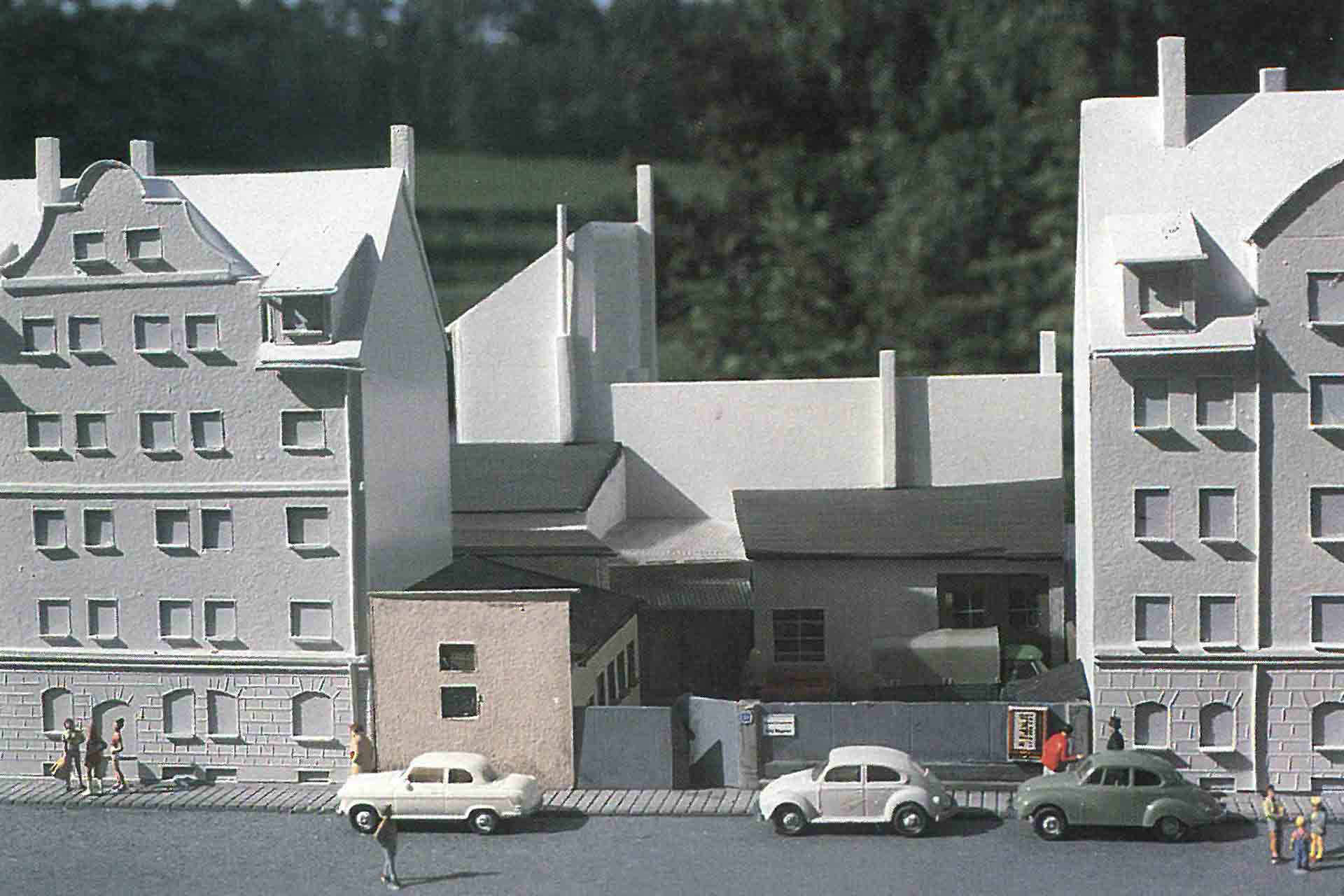

The new company was built in a former car workshop - with a spray shop and office.

Right from the start, Wagener focussed on high quality. "The photo industry's incoming inspections are very tough," he later recalls in his biography. Braun placed more and more orders, so additional injection moulding machines had to be purchased - the largest with a clamping force of 160 tonnes. The rear wall of the company building had to be removed to create space.

Quality control, garden, car park and sanitary facilities.

The location is becoming too small

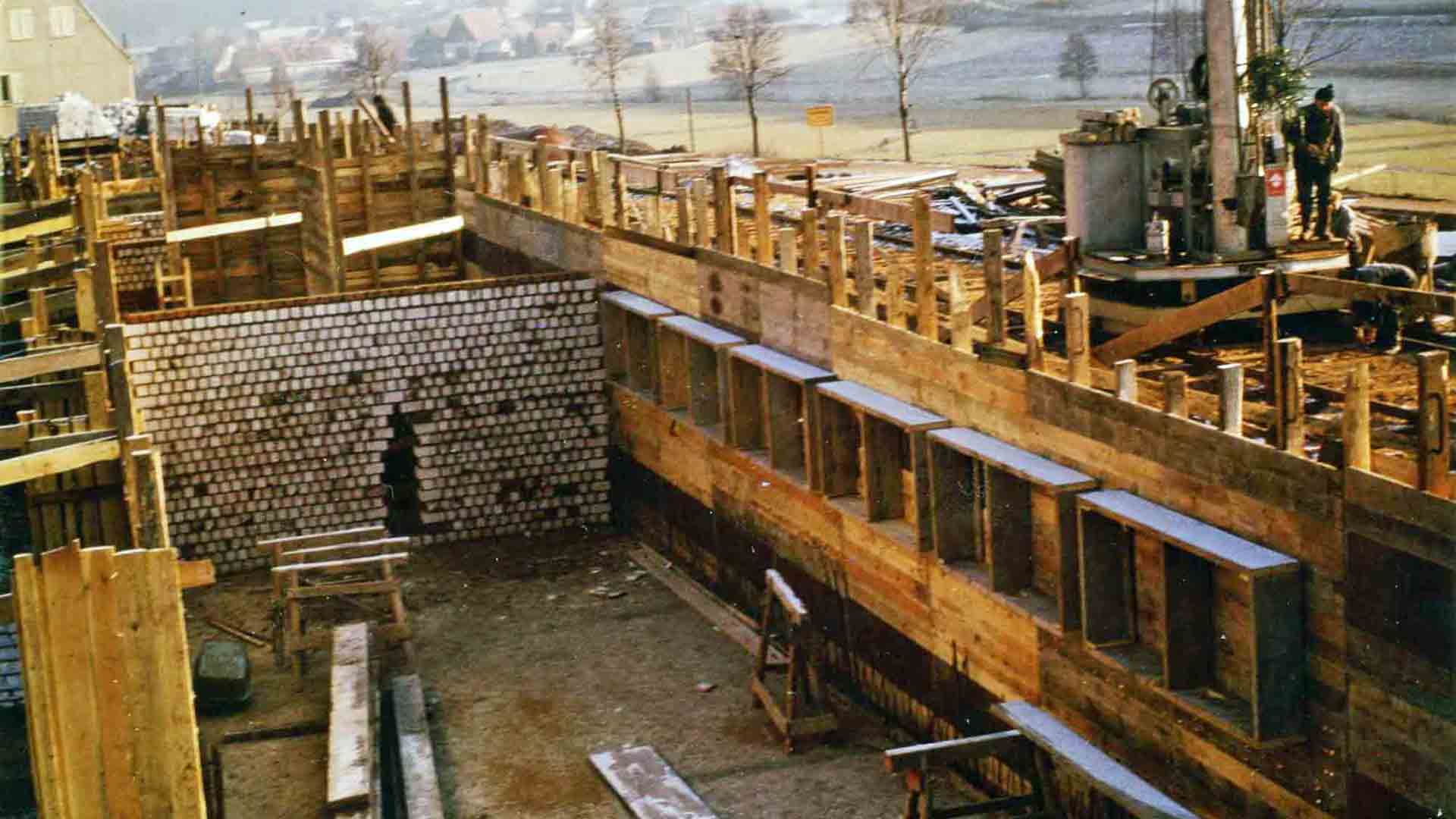

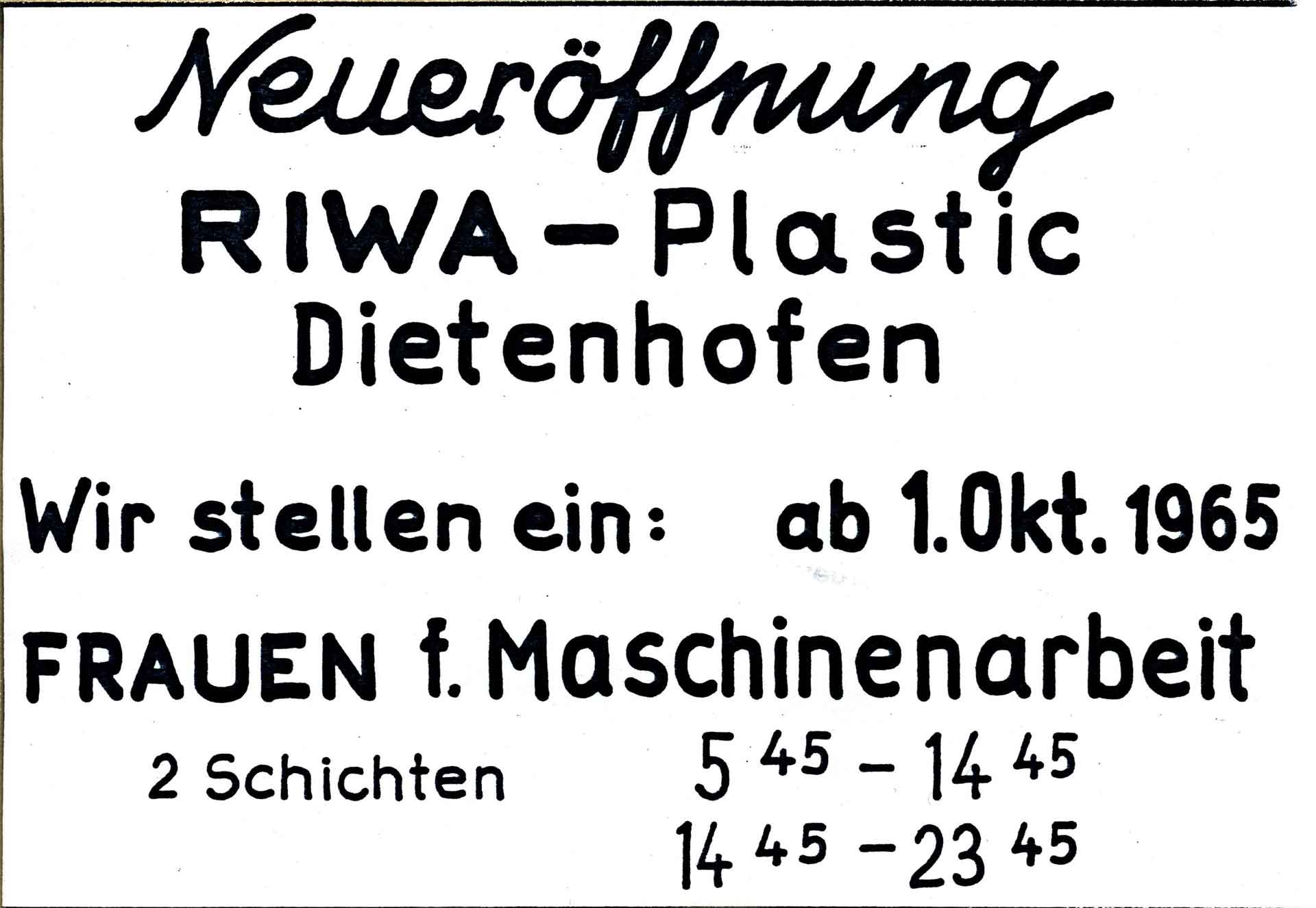

Production kept increasing and the production facility was bursting at the seams. Eventually, the neighbours had had enough of all the night work. A solution had to be found. Fritz Wagener started looking for a production site outside Nuremberg. At first, he favoured Hersbruck, but through personal contacts he finally found the right property and employees in Dietenhofen. Planning began on 11 May 1964, and construction of the 1,000 m² hall on the 40,000 m² site began in September 1964.

The new building in Dietenhofen grew and grew.

The topping-out ceremony was held on 12 July 1965, and the company moved to Dietenhofen on 18 October. The machines were still working in Nuremberg the night before the move took place, during the early shift. Most of the machines were already in Dietenhofen for the late shift. Additional electricians and fitters assisted with recommissioning. A veritable convoy of lorries conveyed the machines to Dietenhofen by road.

The machines were dismantled in Nuremberg and transported by heavy vehicles to Dietenhofen, where they were reinstalled in the new building.

New workers were already being trained in parallel with the relocation, one group at another company in Dietenhofen, a further group is shown being driven to the Nuremberg site in the RIWA staff bus.

The second pillar

As an astute entrepreneur, Fritz Wagener worried about being too dependent on one customer - around 95 per cent of the photo products were being manufactured for the Braun company alone. So, he started looking for another mainstay in the field of plastic injection moulding technology, in order to become more independent. In 1964, the decision was made to take over Herpa. Accessories for model railways were an intriguing production initiative for Wagener, tying in with his personal know-how. One year later, the takeover was complete. This meant accessories for the photographic industry continued to be produced in Dietenhofen under the RIWA name, while accessories for model railways were manufactured under the name of Herpa. Subsequently, other Herpa sites in Beilngries (production) and Nuremberg (sales and despatch) were closed, and the warehouse and despatch department temporarily housed in the Link building in Dietenhofen. Wilhelm Hergenröther continued to work at Herpa as an employee for a while before retiring from the company he had founded. In May 1969, his son Dieter Wagnerer became the commercial manager at Herpa.

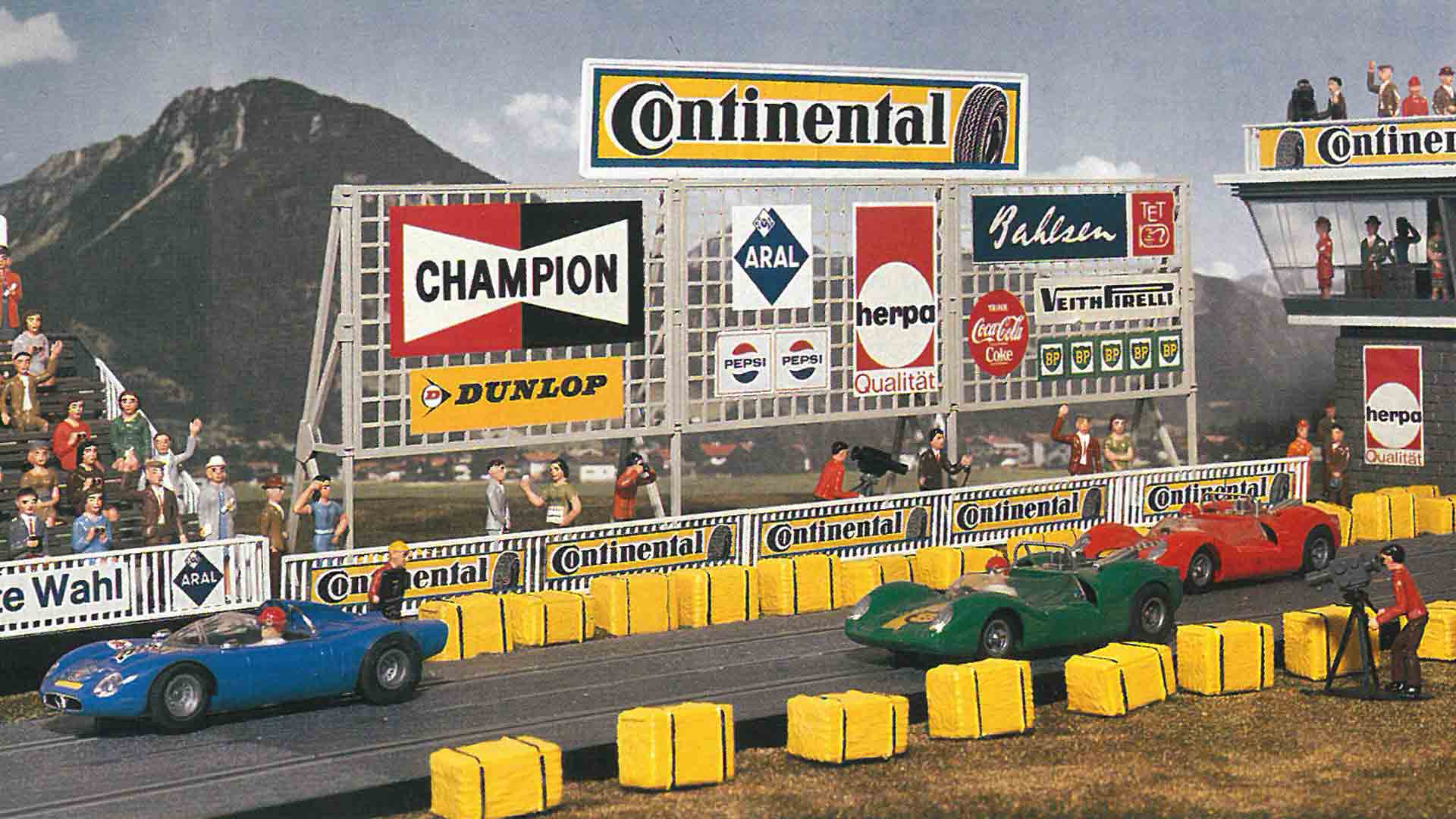

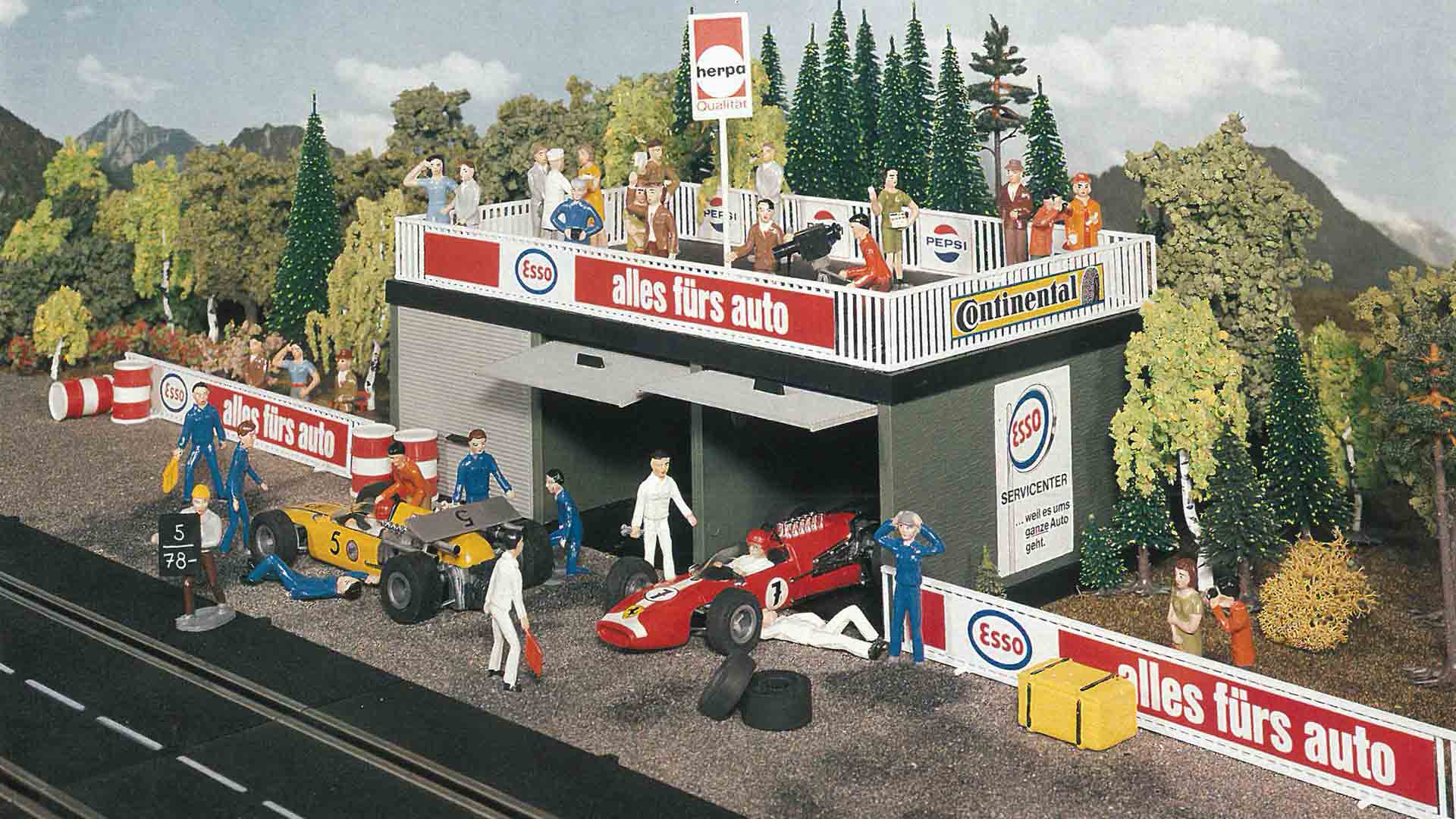

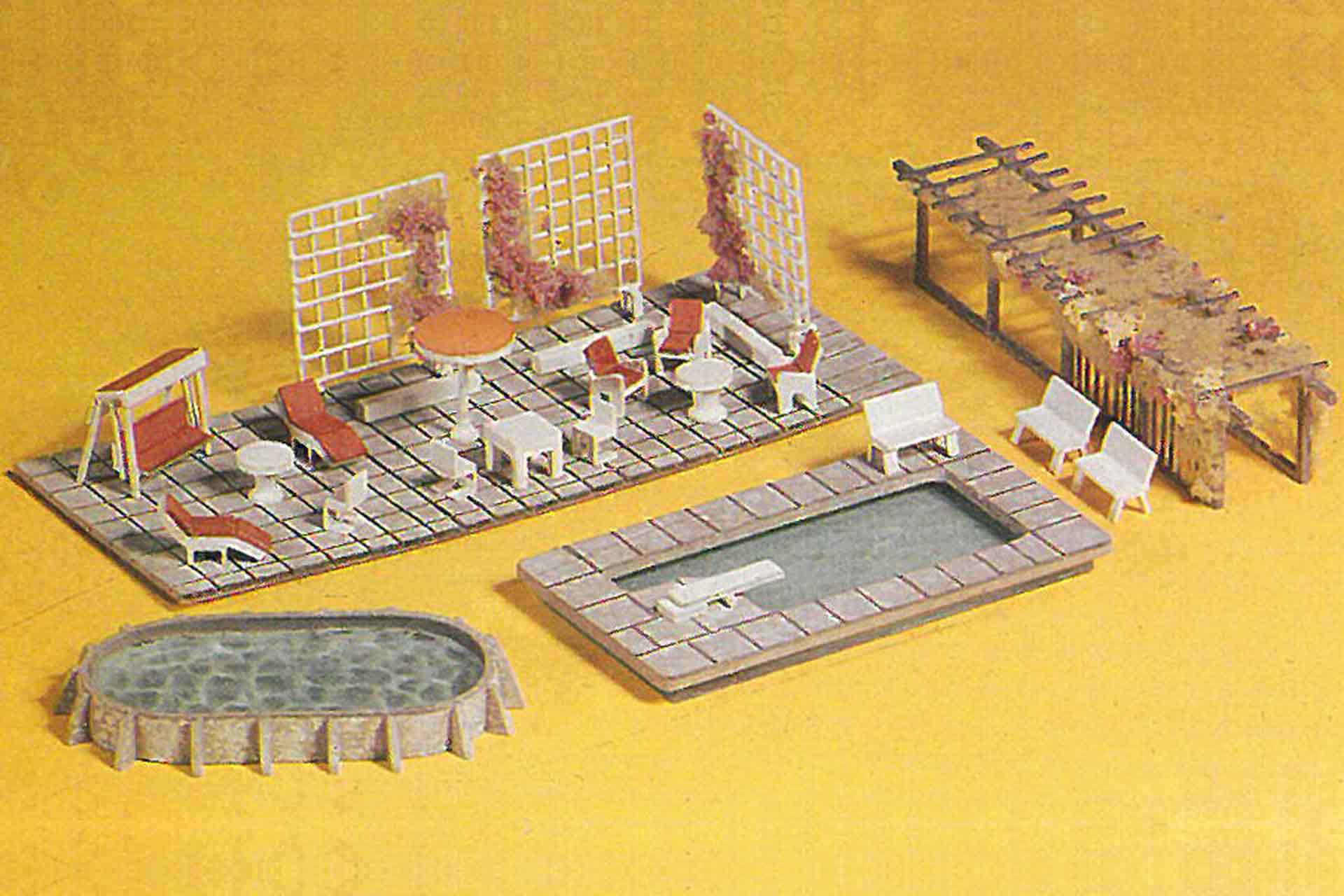

Fritz Wagener went on to expand the Herpa range - it became the first company to produce accessories for electric racetracks, such as spectator stands, racing pits, barrier fences, figures, and the timekeeper's tower.

One year later, building kits for model railways in the 1:60 scale (N gauge) were added – an alpine hotel, mountain church, and chalets, as well as engine sheds and decorative parts. These were so detailed that Herpa quickly made a good name for itself.